Digital Engineering, Advanced Manufacturing and CoAspire’s Commitment to the supporting the Digital Trinity

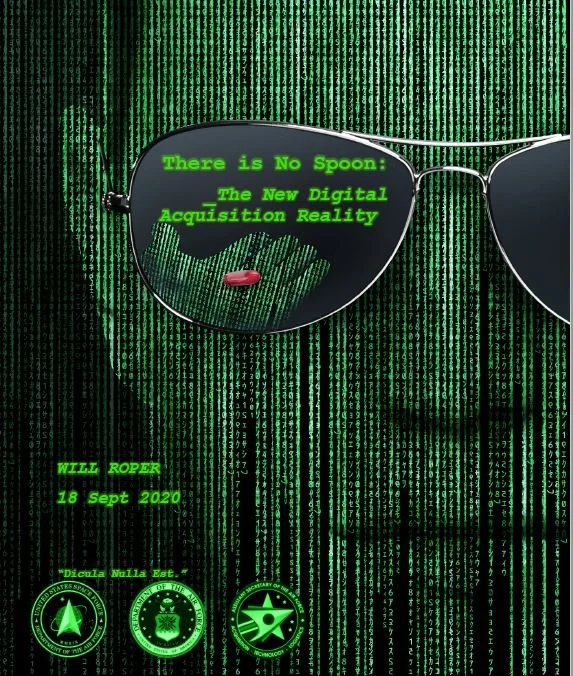

Although 2020 was a year to forget, this document was unquestionably one of the better things to emerge that year. CoAspire first became a disciple of the Digital Engineering movement in 2015.

THE DIGITAL TRINITY…

Is a term coined by the Air Force and supported by the DoD, Department of the Navy and the Army. It is composed of three pillars:

Digital Engineering and Management

Agile Processes; and

Open Systems Architecture

All services in the DoD are heavily invested in transitioning to digital acquisition and breaking vendor lock relationships.

In 2015, CoAspire began working with PTC.com, a global leader in providing a full suite of Digital Engineering empowering software. CoAspire has trained employees in DE software, to include Product Lifecycle Management (PLM) software like Windchill.

CoAspire embraces Agile and has trained employees in Agile methodologies, including its CEO who was certified as a Scrum Master in 2020.

CoAspire is developing RAACM and the Guided Training Round using all three elements of the Digital Trinity.

ADVANCED Manufacturing…

CoAspire supports, through its Digital Engineering activities Advanced (or Additive) manufacturing (AM). AM takes many forms, and CoAspire is fully invested to take advantage of these technologies to lower costs for itself in its own activities, and customers in the development, production, and post-production (obsolescence) phases of a product’s lifecycle.

Here is the real Guided Training Round Part

And here is an AM part that CoAspire built for its Trade Show Model - fake - almost free - but functional. We have Digital Twins fully documented and ready to roll…

Here is the Digital Twin of the GTR

And here it is on display at the Air Armament Symposium in Ft. Walton Beach, Florida. With the AM seeker.